Research about commercial dispersant safety has seen increased efforts to identify benign alternatives and improve current dispersant systems since the Deepwater Horizon oil spill.

Preliminary research suggests that dispersants formulated as gels may be a viable alternative to liquid dispersants and may address certain problems and concerns about Corexit 9500 use and application.

The Gulf of Mexico Research Initiative recently awarded Dr. Vijay John a grant to pursue the development of a surfactant gel dispersant and expand research that he and colleagues conducted about halloysite clay nanotubes as a dispersant delivery system.

John’s team believes that these biodegradable materials could have applications as safe technologies for chemical herding, a process that uses surfactants at the air-water interface to form oil layers thick enough to be burned or skimmed.

John and his team are developing a gel formulation that contains all but two Corexit 9500 components – Span 80 and the solvent propylene glycol – and replaces a significant amount of the potentially harmful surfactant DOSS with lecithin, a food-grade emulsifier.

Surfactants help break up oil by lowering the surface tension at the oil-water interface, and early tests have shown that this new gel formulation reduces surface tension as successfully as Corexit. The team will investigate the physical characteristics of gel-created dispersions and assess the gel’s effect on oil degradation compared to Corexit.

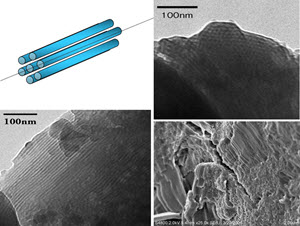

The researchers will then examine if the clay nanotubes could be used to deliver the gel to an oil-water interface, similar to a surface oil slick. Problems with traditional liquid dispersants most often arise during and after their delivery to the ocean surface.

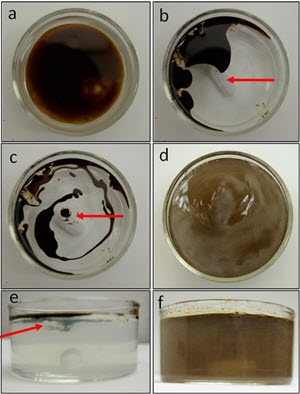

The gel has a crystalline mesoscale structure that ranges from hexagonal to sheet-like and onion-like multilamellar structures. (Images by Olasehinde Owoseni)

Responders apply liquid dispersants as a mist, but it tends to roll off of weathered surface oil and is often washed away before oil can be mitigated. However, nanotubes and naturally buoyant gel dispersants stick to the weathered oil and allow a more direct application of dispersant to an oil spill.

“It’s like a targeted drug delivery system,” explained John. “If you want to deliver drugs to only a tumor and not healthy organs, you have to contain them in something that will target the tumor. We’re trying to do the equivalent in the marine environment using naturally buoyant gel and dispersant-filled nanotubes to target the oil-water interface.”

Vijay John (pictured) and his team are investigating safer, more efficient alternatives to current methods of oil dispersal. (Provided by Paula Burch-Celentano/Tulane University)

The project’s researchers are Vijay John and Diane Blake of Tulane University and Yuri M. Lvov and Donghui Zhang of Louisiana State University. Their project is The Design of Synergistic Dispersant and Herding Systems using Tubular Clay Structures and Gel Phase Materials.

************

The Gulf of Mexico Research Initiative (GoMRI) is a 10-year independent research program established to study the effect, and the potential associated impact, of hydrocarbon releases on the environment and public health, as well as to develop improved spill mitigation, oil detection, characterization and remediation technologies. An independent and academic 20-member Research Board makes the funding and research direction decisions to ensure the intellectual quality, effectiveness and academic independence of the GoMRI research. All research data, findings and publications will be made publicly available. The program was established through a $500 million financial commitment from BP. For more information, visit http://gulfresearchinitiative.org/.